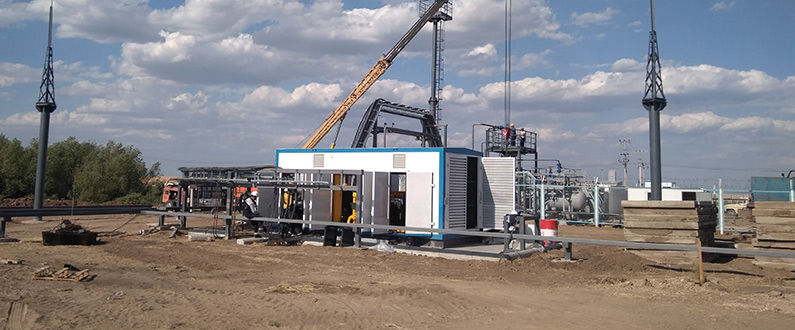

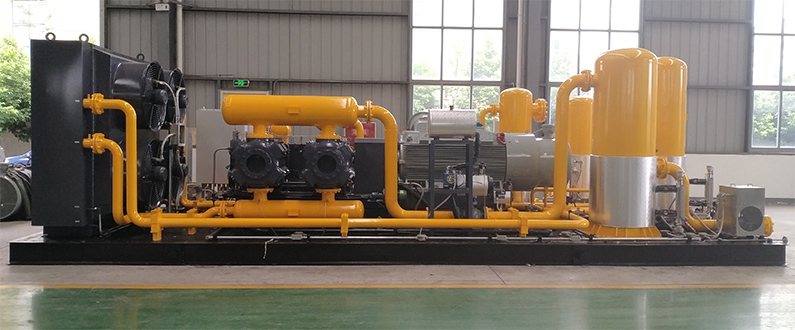

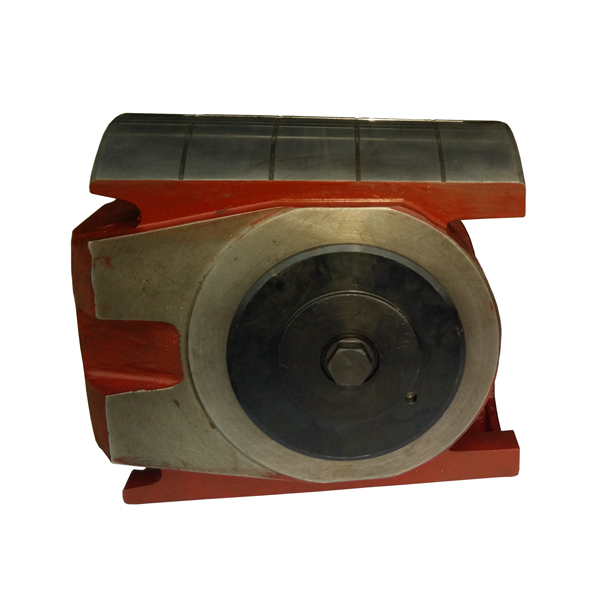

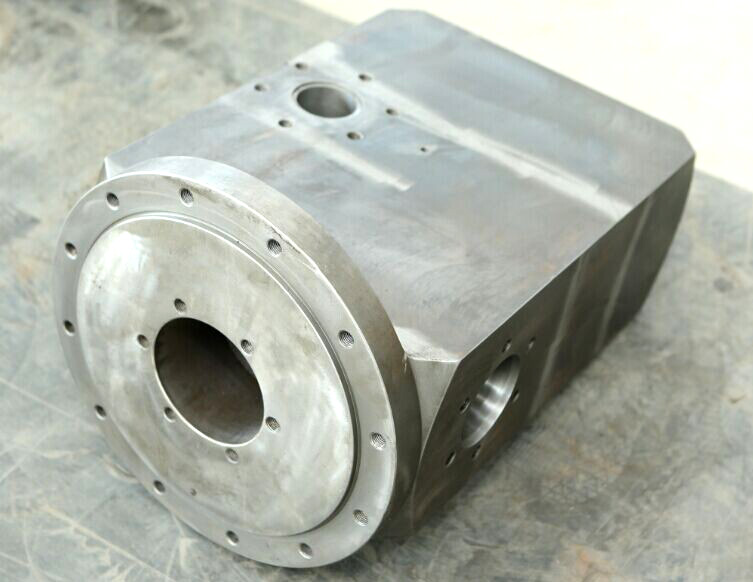

Associated Gas Compressors are uesed to create a pressure differential by pulling the gas form the wells,boosting gas and pushing it into the gathering system.Reciprocating compressors are ranged from one to five stages,which are driven by electric motor,gas engine or diesel engine.Compressors are located at wellhead or in a trunk line being fed by several reservoirs.Compressor packages are skid-mounted and can be relocated if necessary.

Applications

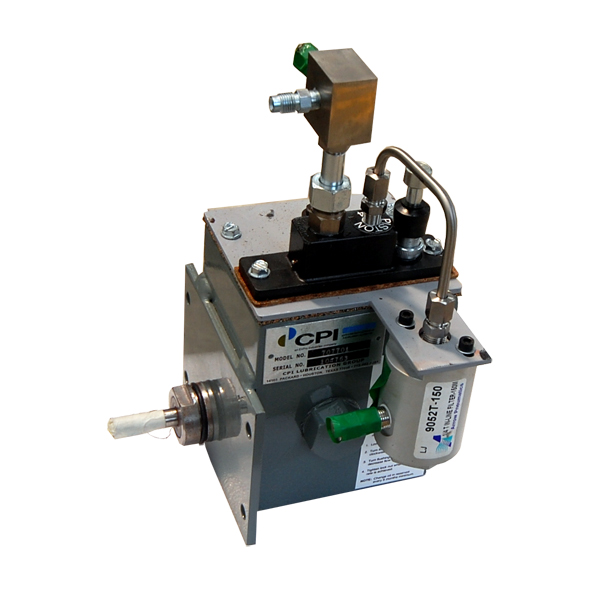

We offer application kinds of gas components, engineered to ensure the performance, safety,and reliability of your wellhead gas gathering operation. These include safety options and corrosion resistant materials for those gathering applications where the gas contains acidic or toxic components, such as hydrogen sulfide and carbon dioxide,etc.

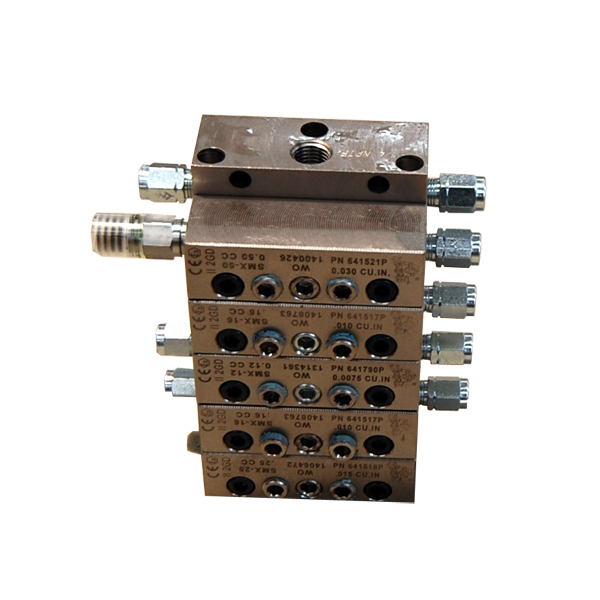

These options include but not limited to:

Stainless Steel materials for piston rods and valves,

Two compartment distance pieces,

Purged packing case,

Special heat treatment for pressure vessels and welded connections...

Associated gas is a mixture of hydrocarbons obtained during the oil extraction and separation processes; it mainly consists of methane (CH4), ethane (C2H6), propane (C3H8), butane (C4H10) and isobutane (iC4H10) and may also include admixtures of various composition and phase state.

When crude oil is extracted from wells, it will contain significant quantity of dissolved hydrocarbon gas. This is usually known as associated gas. The start of the oil processing is to reduce the pressure of the oil stream and thus flash off dissolved gas. This can typically happen three times at reducing pressures, according to what the inlet pressure from the well is. This flashed gas needs to be then re-compressed for further dehydration and export to sales line pressure. We can use rotary vane, oil flooded screw and oil lubricated reciprocating compressors for this application.